Difference between revisions of "518"

(+product page link) |

|||

| Line 1: | Line 1: | ||

[[File:518 photo.jpg|thumb|Model 518]] | [[File:518 photo.jpg|thumb|Model 518]] | ||

| − | [http://www.sensoray.com/products/ | + | [http://www.sensoray.com/products/518.htm Model 518] is an advanced, eight-channel sensor measurement system on a PC/104 board. It provides excitation for passive sensors and signal conditioning for thermocouples, RTDs, thermistors, and strain and pressure gauges. Each channel can be individually configured to measure voltage, resistance, or any supported sensor type. |

{{clear}} | {{clear}} | ||

Revision as of 11:45, 1 September 2016

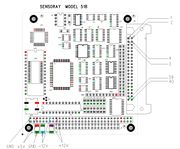

Model 518 is an advanced, eight-channel sensor measurement system on a PC/104 board. It provides excitation for passive sensors and signal conditioning for thermocouples, RTDs, thermistors, and strain and pressure gauges. Each channel can be individually configured to measure voltage, resistance, or any supported sensor type.

-12V power supply

- My SBC does not provide -12V power to the PC/104 stack. Does the 518 require -12V power?

Yes, the 518 requires -12V, so your SBC must provide this operating voltage to it. SBCs usually have some sort of provision for this because the PC/104 specification mandates -12V (though some SBC suppliers omit it to reduce costs).

You can easily check for the presence of the three required power supply voltages (+5V, +12V, -12V) by probing test points shown in the image on the right.

Sensor data is all zeroes

- Sensor data is all zeroes after a reset. What could be the problem?

First verify that you have applied the required power supply voltages to the board. If so, the problem may be caused by not waiting long enough after a board reset.

An A/D conversion is not invoked when you fetch sensor data; this simply returns the most recently acquired sample. If no conversions have been performed yet, the sensor data will be zero. When the board is reset, it will perform a calibration cycle before it starts scanning sensors. So, after a reset, you must wait long enough for a calibration cycle, plus a complete scan of all sensors, before you will be able to read valid data (approximately 350 ms).